News

Grasping the pulse of the industry and measuring industry trends

Analysis of the Production Scale of Industrial Robots in China from 2020 to 2024

Analysis of the Production Scale of Industrial Robots in China in 2019

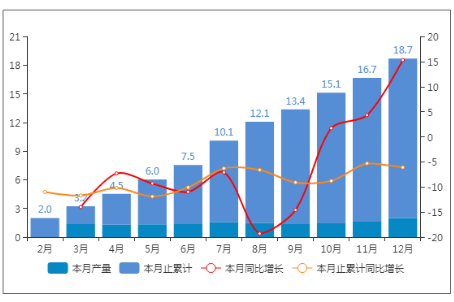

The Investment Analysis and Outlook Forecast Report on China's Robotics Industry from 2020 to 2024 released by China Investment Research Institute shows that from January to December 2019, the cumulative production of industrial robots in China was 186900 sets, a year-on-year decrease of 6.1%. Among them, the highest production of industrial robots was in December, with 20000 sets, a year-on-year increase of 15.3%; Next was November, with a monthly output of 16100 units, a year-on-year increase of 4.3%; At least in April, the monthly production was 12900 sets, a year-on-year decrease of 7.3%.

Chart 2019 National Industrial Robot Production Data

Unit: 10000 sets,%

Data source: National Bureau of Statistics

Comprehensive Evaluation of Investment Value in China's Robot Industry

Four dimensional evaluation table for investment value in the robotics industry

Data source: China Investment Industry Research Institute

The "Investment Analysis and Outlook Forecast Report on China's Robot Industry from 2020 to 2024" released by the China Investment Industry Research Institute shows that economic, technological, and policy factors are the main driving forces for the development of robots in China:

The downstream application fields of robots are constantly expanding, and technology is gradually maturing, driving the prices of robot products to continuously decrease. Central and local governments have introduced policies to support the robot industry.

The industry has high barriers to entry:

The competitive barriers are very high, and international robotics giants firmly control core technologies. In addition, they believe that both financial and technological barriers are relatively high.

The robotics industry has entered the mid-term of growth:

China has become the world's largest demand market for robots, and major foreign companies are vying to build factories in China. Newly entered domestic enterprises need to face fierce competition.

Comprehensive evaluation: The investment value rating is three stars, and the investment recommendation is "recommended".

Market Outlook and Demand for China's Robot Industry

1、 The robotics industry has risen to the national strategic level.

Developed countries such as the United States, Europe, Japan, and South Korea have long attached great importance to the development of the robotics industry and have launched national strategic plans to develop the robotics industry. China is currently in a decisive stage of building an innovative country and must rely more on technological innovation to lead and support economic development. Therefore, with technological innovation as the core, vigorously developing China's national brand robot industry is imperative for the adjustment of China's economic development model and industrial structure. In June 2014, Xi Jinping highlighted that robots are "the pearl at the top of the manufacturing crown" at the conference of the Chinese Academy of Sciences and the Chinese Academy of Engineering, which is an important symbol to measure the level of scientific and technological innovation and high-end manufacturing in a country. The robot revolution is affecting the global manufacturing landscape, undoubtedly pushing the development of the robot industry towards a national strategic level.

2、 The new manufacturing model under Industry 4.0.

The theme of Industry 4.0 is intelligent manufacturing and smart factories. The core of Industry 4.0 is to build an information physical system. Through the Internet of Things and the Internet, the exchange and interaction of data and information between things, machines and machines, and machines and people will be realized. That is, equipment, production lines, products, factories, suppliers, and customers will be closely connected to establish an intelligent factory to achieve intelligent production. The "Industry 4.0" proposed by Germany and the "Industrial Internet" launched by the United States are both manifestations of the integration of "industrialization and informatization". In the future society, countless machines, factories, workshops, and people will be connected through a big network, and through big data technology analysis, we will vigorously reduce the losses in the manufacturing process. Industry 4.0 will drive a global wave of intelligent manufacturing upgrades and achieve changes in manufacturing models across numerous industries.

3、 The blueprint for "Made in China 2025" to move towards an industrial powerhouse.

Premier Li Keqiang clearly stated in the government work report that the implementation of "Made in China 2025" will adhere to innovation driven, intelligent transformation, strengthening foundation, and green development, and accelerate the transition from a manufacturing powerhouse to a manufacturing powerhouse. The core of the plan is to promote the deep integration of industrialization and informatization, develop and utilize technologies such as networking, digitization, and intelligence, and focus on seizing opportunities and achieving breakthroughs in some key areas to accelerate the transformation and upgrading of the manufacturing industry. In the plan, it is the first time to propose the development of "Internet plus" action plan, and the concept of "industrial Internet" appears for the first time to promote the integration of mobile Internet, cloud computing, big data, Internet of Things, etc. with modern manufacturing. The starting point of planning is to seize the commanding heights of intelligent manufacturing in the new round of industrial revolution.

4、 The development potential of China's robotics industry is enormous.

The "Investment Analysis and Outlook Forecast Report on China's Robot Industry from 2020 to 2024" released by China Investment Industry Research Institute shows that with the structural shortage of labor and the sharp increase in labor costs, the era of labor dividend in China is coming to an end, facing an urgent need for industrial transformation and upgrading, which has ushered in a spring of great development for the domestic robot industry. The density of robots in China is significantly lower than that of developed countries such as Germany and Japan. There is a huge gap in demand and supply in the Chinese robot market, and the future market space is huge. This will provide strong impetus for China to concentrate resources and develop the domestic robot industry.

Source: China Robotics Network

Backtop

Scan and follow us